The application of PEEK is attributed to its unique material properties, including high temperature resistance, chemical corrosion resistance, good mechanical properties and electrical insulation, as well as ease of processing.

It can withstand continuous working temperatures up to 260°C, with short-term use temperatures reaching 300°C, making it suitable for high-temperature environments. PEEK has high tensile and compressive strengths, as well as excellent wear resistance and impact resistance. It is resistant to most chemicals, including acids, alkalis, solvents, and other chemical substances.

It has self-lubricating properties and a low coefficient of friction, thus requiring no additional lubricants in moving parts, which reduces wear, energy consumption, and maintenance needs.

PEEK has low hygroscopy, maintaining its mechanical properties and dimensional stability even after prolonged exposure to water and high-temperature high-pressure steam.

Of course, there are also drawbacks: PEEK is expensive, and it has high requirements for processing equipment and parameters, necessitating specialized processing techniques and equipment.

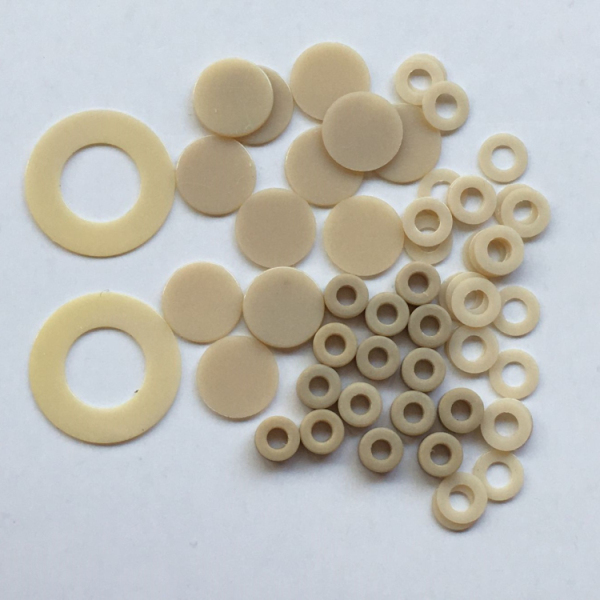

Applications include connectors and circuit board components in electronic devices, semiconductor manufacturing, LED packaging, sensor shells, battery components, fiber optic communications, and more.

In, PEEK material has been widely used in various fields due to its excellent comprehensive performance, but factors such as